Can Sustainability Be Globally Driven and Locally Accomplished? Astellas believes it can.

With average global temperatures continuing to rise, addressing climate change has become an even more urgent task. Astellas is committed to forging a sustainable future and has embarked on a transformative path toward achieving Net Zero by 2050 (click here to learn more), tackling the intricate task of reducing its carbon footprint by blending a global perspective with localized actions.

To better understand Astellas' initiatives, we hear from two employees who are actively making a difference. Christina Chalé in the Sustainability division is leading the way toward Astellas' sustainability goals. She explains the company's global approach to tackling climate change.

Meanwhile, at Astellas' Kerry plant in a picturesque corner of Ireland, Megan Staunton, a facilities energy engineer in the Manufacturing & Technology division, shares an inspiring story of how a proactive community is spearheading impactful and tangible sustainable changes.

“As a pharmaceutical company, our motivation to address climate change stems from the understanding that sustainable growth for society and Astellas requires active engagement with the key issues facing the planet. We are focused on multiple areas, including utilizing renewable energy sources and reducing greenhouse gas emissions throughout our business operations as we progress toward our long-term target of Net Zero by 2050. In January 2023, we have secured certification from the Science Based Targets initiative (SBTi) for our reduction targets, signifying our dedication to a trajectory that aligns with the objectives of the Paris Agreement.” (Click here to learn more.)

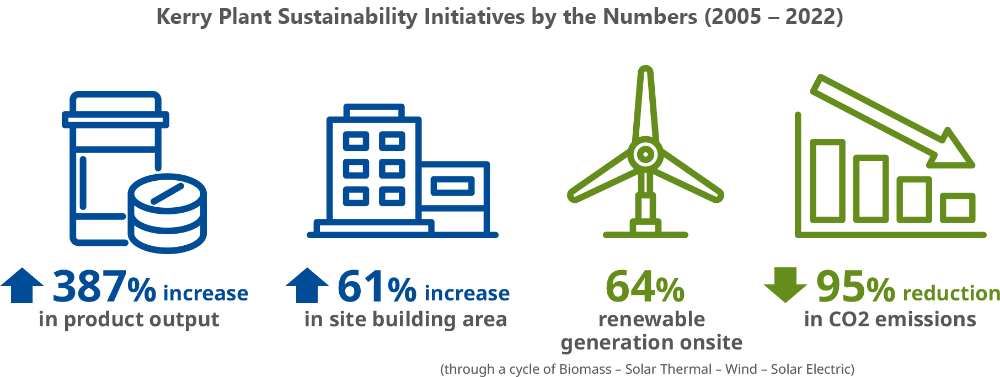

“Our Kerry Plant in Ireland is an excellent illustration of how we can achieve holistic sustainability practices involving the broader community and inspire behavioral changes. The plant serves as a crucial component of the company's international presence by manufacturing products for approximately 100 countries, and the sustainability initiatives in practice at the plant—including investments in wind turbine power and biomass-fueled boiler equipment—align seamlessly with Astellas' Net Zero ambitions.

As we continue to expand our implementation of renewable energy solutions across Astellas' manufacturing sites, the Kerry plant stands at the forefront, setting a remarkable example for the industry. We continue our journey to secure a more sustainable future and enhance the efficient production of vital medications for the well-being of patients worldwide.”

“The journey toward the Kerry Plant's sustainability is deeply intertwined with its roots in our community. Since its establishment in 1992, we (Astellas) have always been ingrained in the fabric of Kerry. Being a significant employer in the area, the company has strived to foster growth and expansion within the community while also seeking the active involvement of its residents.

“The commitment to sustainability took a more defined shape in the early 2000s when corporate directives and local regulations emphasized the importance of environmental management. As early as 2003, the Kerry Plant obtained accreditation for the International Standard for Environmental Management (ISO 14001), solidifying the company's dedication to embedding sustainability practices into our operations. The Kerry Plant then made a further transformative step in 2011 with the implementation of wind turbine and biomass projects.”

Local solutions to address a global challenge

“The Kerry Plant exemplifies how embracing local solutions are key to combatting climate change. Due to the absence of natural gas pipelines in our area of Ireland, the plant relied on oil for operations. However, recognizing the environmental and economic drawbacks, we began to seek alternatives. We needed to find a way to reduce our reliance on emission-intensive fuel and navigate the soaring oil prices, so we turned to local solutions to overcome this complex reality.

“The solution came in the form of a biomass boiler, which utilizes wood chips derived from the waste wood of the local forestry industry (within a 50-kilometer radius of the plant). This boiler proved to be both an environmentally friendly and cost-effective alternative to oil, significantly reducing our greenhouse gas emissions and costs. Considering the plant's expansion over the last decade (around 60%), Kerry would have required approximately 1.2–1.3 million liters (about half the volume of an Olympic-size swimming pool) of oil to function in 2022, however, our biomass boiler reduced this amount to just 70,000 liters (approximately 94-95% reduction).”*

* Oil is used in the Kerry Plant as a backup to ensure business continuity of critical utilities.

Employee voices championing sustainable change

The combination of senior management support and all staff members' engagement has been key to the success of the Kerry Plant's sustainability initiatives.

Across the site, employees actively propose and champion various eco-friendly projects; for example, the installation of nearly 20 electric car charge points onsite was driven by the staff's genuine interest in reducing their carbon footprint. The plant has also achieved zero waste going to landfills by implementing practices such as separating food, plastic, paper, and composting. Our composter feeds into the biomass boiler, creating a real circular economy. This achievement results from extensive teamwork and collaboration and this ethos is deeply ingrained in employees’ actions.

The Kerry plant also acts upon global sustainability initiatives. Labs inherently involve significant usage of single-use plastics and chemicals, making them resource-intensive, and therefore the United Nations Framework Convention on Climate Change aims to have 95% of pharmaceutical and biopharma labs adopt environmentally friendly practices by 2030 as part of their Race To Zero campaign. The plant upgraded its lab around 2022. The lab already excelled in recycling and energy conservation, but to further enhance sustainability efforts, they improved the efficiency of all equipment. Currently, behavioral-based programs are ongoing to foster collaboration among lab staff and encourage thoughtful actions.

The Kerry Plant’s ARK building achieved the Gold level of LEED*2 certification.

Solar panels on the plant’s ARK Building roof provide 10% of its electrical load.

*2 The non-profit organization USGBC (U.S. Green Building Council) develops and operates a certification system for evaluating environmentally friendly buildings. The certification process is carried out by GBCI (Green Business Certification Inc.), an independent third-party organization.

Driven to succeed by patients and the community

Alongside internal efforts, the plant is also actively involved in external initiatives. Megan explains, “Beyond these internal efforts, we actively engage with local Kerry schools in various environmental initiatives. For example, employees support schools to become more eco-friendly advising on promoting energy conservation, waste management, and water conservation. We also organize school cleanups and beach cleanups. We believe that committing time to support local schools on climate change education fosters eco-consciousness and empowers young minds to become future advocates for sustainability.”

“As an Astellas employee and a member of a close-knit community, I am deeply conscious of the two key indicators that drive our work: patients and the community. Every day, we are driven by the profound purpose of developing life-saving drugs. It is a tremendous privilege to know that what we do matters in such a significant way. In drug production, quality is paramount but ensuring that our actions are sustainable is equally important, considering the profound relationship between our work and the well-being of patients and the community. This awareness is the underlying tone that guides everything we do. Patients and community are the leading lights illuminating our path.”

Discover more about the Kerry Plant's sustainability initiatives, including its numerous energy and environmental achievement accolades, and find out how Astellas is demonstrating sustainability in action.

Related Links